State of the Art Infrastructure

Infrastructure

Our team is our greatest asset. Each member brings unique skills and perspectives, creating a diverse and versatile group.

Infrastructure Overview

Leading the Future of Utility

Smart Metering Infrastructure

We have established a robust and scalable smart metering infrastructure, operating state-of-the art manufacturing facilities in Delhi.

Our operations are fully integrated—from design and manufacturing to testing and quality assurance—enabling end-to-end control, product traceability, and high efficiency. Continuous upgrades ensure our manufacturing processes align with evolving market demands and technological innovation.

SMT | EMS Plant:

Our state-of-the-art SMT (Surface Mount Technology) and EMS (Electronics Manufacturing Services) facility is designed to deliver precision, efficiency, and high-volume output. The facility operates within a climate-controlled, dust-proof, and electrostatic discharge (ESD) protected environment, ensuring optimal conditions for electronics manufacturing.

We house an advanced PCB assembly unit equipped with high-speed SMT lines sourced from leading global manufacturers. Our combined installed capacity enables us to mount up to 500,000 components per hour. These lines are capable of handling a wide range of component types and sizes, offering flexibility in design and high throughput in production.

The assembly process is further strengthened by automated optical inspection (AOI) and solder paste inspection (SPI) systems, which help maintain consistent quality and minimize errors. Our facility also includes automated conveyorized component mounting lines, wave soldering machines, and other advanced automation systems to enhance production efficiency and assembly precision.

With robust process control, versatile handling capabilities, and a focus on manufacturing excellence, our SMT | EMS infrastructure is built to support the complex needs of modern electronics and smart metering applications.

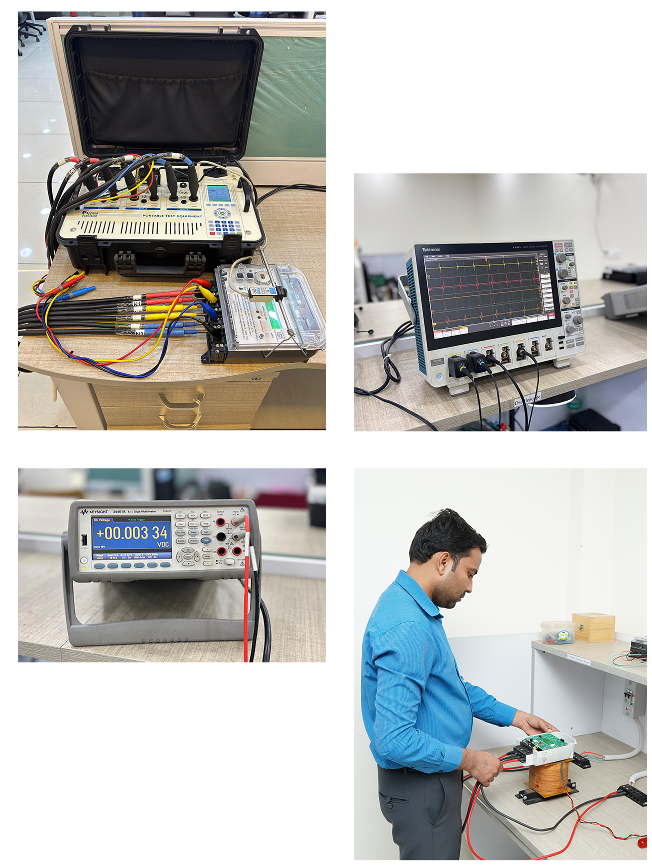

In-House R&D Center:

Our in-house Research and Development (R&D) center is a CMMI Level-3 certified facility recognized by the Department of Scientific and Industrial Research (DSIR). It serves as the driving force behind our innovation in smart metering technologies. Our multidisciplinary team brings expertise in mechanical design, electronics hardware and firmware, and software development.

We have successfully executed several cutting-edge R&D projects, including utility automation and IoT-based solutions in collaboration with reputed technical institutions, under the guidance of the Ministry of Science and Technology. These initiatives showcase our ability to deliver high impact solutions for complex national challenges.

Driven by an agile work culture and a commitment to fast turnaround times (TAT), our R&D function consistently delivers results that align with industry trends and client expectations. This agility enables us to quickly adapt to changing requirements and bring new solutions to market with speed and precision.

Our innovation journey has seen us expand from basic single-phase static meters to a broad range of smart metering products — including LCD-enabled devices, multi-communication technology platforms, dual source dual register (DRDR) meters, prepaid metering systems, and advanced smart meters equipped with intelligent data management capabilities. These advancements reflect our deep understanding of evolving utility needs and our dedication to delivering futureready solutions.

In-House Tool Room:

Our in-house tool room is a vital enabler of our precision manufacturing capabilities. Leveraging

advanced design software such as SolidWorks and Siemens NX, we develop high-accuracy molds

and dies for a variety of plastic and sheet metal components.

The facility is equipped with cutting-edge CNC machines, wire-cut machines, and electrical discharge machines (EDM), allowing us to achieve quick mould manufacturing without compromising on quality. This speed and precision significantly reduce development time and support rapid production cycles.

We maintain a high standard of performance through in-process quality assessments, along with the use of automation tools and precision jigs, which contribute to high production efficiency and low rejection rates. Compared to industry peers, our manufacturing processes stand out for their agility, consistency, and overall operational excellence.

Testing and Quality Lab:

Our testing unit, certified by the National Accreditation Board for Testing and Calibration Laboratories (NABL), is equipped with automated testing systems from ZERA and MTE, enabling precise and efficient quality assessments. This computerized setup supports a wide range of critical tests, including acceptance testing, anti-tamper verification, and data validation, ensuring

full compliance with functional and operational specifications.

To further ensure long-term product reliability, we employ advanced testing technologies such as Highly Accelerated Life Testing (HALT) and impulse and surge test equipment. These methods help simulate real-world stress conditions, guaranteeing the durability and stability of our products over time.

Automated Assembly Lines:

Our manufacturing operations are built for speed, precision, and consistency. We operate on conveyorized assembly lines within climate-controlled and dust-free environments, ensuring optimal conditions for sensitive electronic manufacturing.

To maximize efficiency and minimize rejection rates, we utilize in-house developed automated jigs and fixtures, along with automated calibration and testing systems. These tools are engineered to deliver consistent performance with minimal manual intervention.

At the core of our operations lies a custom-developed Manufacturing Execution System (MES), seamlessly integrated with SAP ERP. This digital infrastructure enables Real-time material tracking, End-to-end product traceability, Data-driven quality compliance Together, these capabilities form a responsive, intelligent production system that minimizes downtime and ensures that every product meets stringent quality standards before it leaves our facility.

Infrastructure Overview

Leading the Future of Utility

Wire and Cable Infrastructure

At the core of our Wire & Cables division lies a robust and future-ready infrastructure that ensures the highest quality, performance, and reliability across all our products. Our facilities are engineered to deliver precision, efficiency, and innovation at every stage of production.

Key Highlights of Our Infrastructure

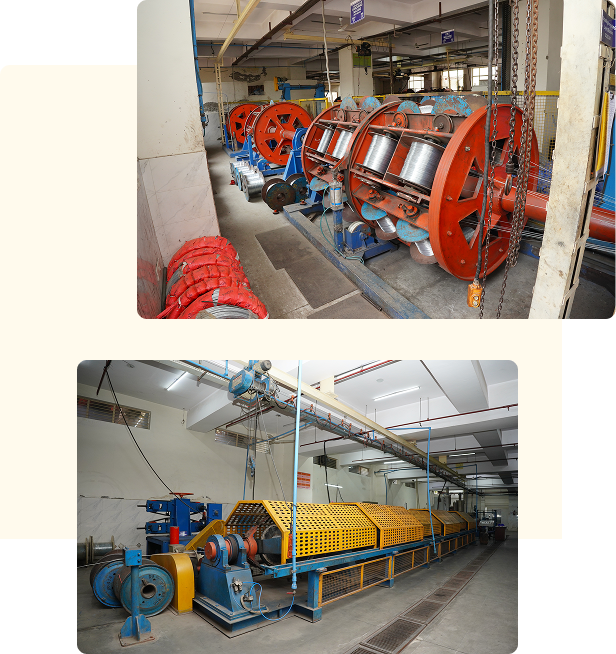

WIRE DRAWING FACILITY

Our dedicated in-house wire drawing units for copper and aluminium wires provide full control over

quality and consistency, ensuring superior conductivity and mechanical strength.

State-of-the-Art Insulation & Sheathing Lines From Supermac

Our state-of-the-art SMT (Surface Mount Technology) and EMS (Electronics Manufacturing Services) facility is designed to deliver precision, efficiency, and high-volume output. The facility operates within a climate-controlled, dust-proof, and electrostatic discharge (ESD) protected environment, ensuring optimal conditions for electronics manufacturing.

Anti-Torsion Stranding & Laying Machines

Precision anti-torsion machinery enables uniform stranding and laying, enhancing the flexibility and lifespan of the cables even in demanding applications.

Armouring Excellence

Our double steel tape, wire, and strip armouring lines deliver added mechanical protection and robustness, making our cables ideal for industrial and heavy-duty usage.

Key Highlights of Our Infrastructure

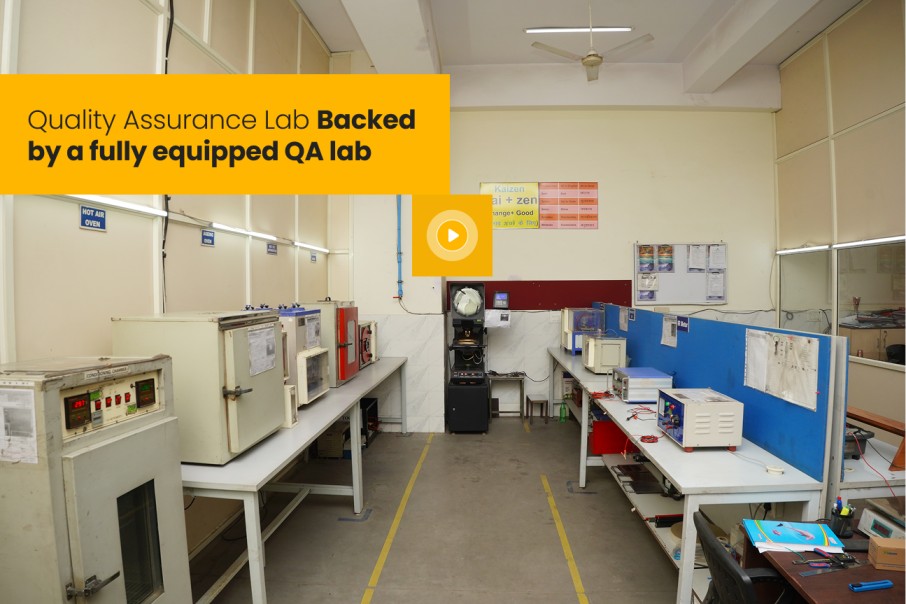

QUALITY ASSURANCE LAB

Newsletter

Stay updated with the latest in smart metering, automation, and energy innovation.

Subscribe now to receive insights, product updates, and event highlights—straight to your inbox.